DUCTILE IRON

What is Ductile Iron?

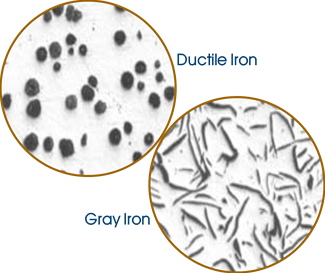

In 1943, in an effort to create an iron with better mechanical properties than either gray or malleable iron, Keith Dwight Millis made a ladle addition of magnesium (as a copper-magnesium alloy) to cast iron while working in the International Nickel Company Research Laboratory. The resulting castings contained not flakes, but nearly perfect spheres of graphite. This discovery opened the door to dramatic new possibilities in metal applications. Ductile iron offers versatility and high performance at low costs. Since 1948, ductile iron castings have proven to be an effective, lower cost alternative to malleable iron castings, steel forgings and steel fabrications. High Tensile Strength, yield strength and elongation combine to give ductile iron a superior strength to weight ratio that adds up to more strength for less expense.

In 1943, in an effort to create an iron with better mechanical properties than either gray or malleable iron, Keith Dwight Millis made a ladle addition of magnesium (as a copper-magnesium alloy) to cast iron while working in the International Nickel Company Research Laboratory. The resulting castings contained not flakes, but nearly perfect spheres of graphite. This discovery opened the door to dramatic new possibilities in metal applications. Ductile iron offers versatility and high performance at low costs. Since 1948, ductile iron castings have proven to be an effective, lower cost alternative to malleable iron castings, steel forgings and steel fabrications. High Tensile Strength, yield strength and elongation combine to give ductile iron a superior strength to weight ratio that adds up to more strength for less expense.

Ductile Iron Cost Savings

When compared to steel and malleable iron castings, ductile iron offers further cost savings. Like most commercial cast metals, steel and malleable iron decrease in volume during solidification, and as a result, require attached reservoirs of liquid metal to offset the shrinkage and prevent the formation of internal or external shrinkage defects. The formation of graphite during solidification causes an internal expansion of ductile iron as it solidifies. This property of ductile iron reduces requirements for feed metal as well as material and energy requirements, resulting in substantial cost savings.

For more information on the advantages of Ductile Iron, see the Ductile Iron Society article, "Why Convert to Ductile Iron?"

Ductile Iron Production Capabilities

Metal Technologies currently has the capacity to produce 110,000 tons of ductile iron each year. Our casting sizes range from 1 lb. to 40 lbs. We produce all standard grades of ductile iron including 65-45-12, 80-55-06, and 100-70-03 as well as austempered ductile iron, and customer specific grades.

Ductile Iron Class Production by Foundry

|

65-45-12

|

80-55-06

|

100-70-03

|

| MTA |

|

X

|

X

|

RDI

|

X

|

X

|

X

|

| NF

|

X

|

X

|

X

|