Ravenna Ductile Iron

Metal Technologies Ravenna Ductile Iron (RDI) facility is a ductile iron foundry specializing in high volume and high requirement castings. Quality and production at this foundry are set up to meet casting requirements for safety and braking applications. RDI processes a significant portion of their products through automated trim cells or CNC grinders that help contribute to a safer work environment for our employees and maximum quality for our customers.

Facility Information

| Capacity: |

55,000 tons |

| Material: |

All standard grades of Ductile Iron including 100-70-03, 80-55-06, and 65-45-12 |

| Melt: |

3 Induction furnaces with 20 tons per hour capacity |

| Molding: |

One Disa 230-B molding line

One Disa 231-B molding line

|

| Finishing: |

One 28 ft3 Tumble Blast

Two 34 ft3 Tumble Blasts

Four Automated Barinder CNC Grinding Units

One AFS High Capacity Flexible Fully Automated Trim & Inspection Cell

Two Neff Trim Processing Cells

Optical Brinell Tester

Sonic and Ultrasonic NDT Capability

Real Time X-Ray Unit |

| Quality: |

IATF 16949:2016

ISO 9001:2015

ISO 14001:2015 |

Industries Served

Industries Served

Automotive, Heavy Trucks, Hydraulic, Rail, and Small Engine

Casting Type and Size

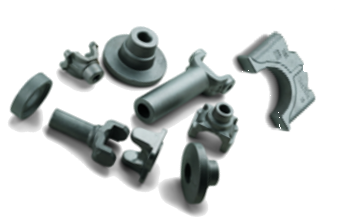

1 to 40 lbs. (.45 to 15.88 kg) High complexity cored and non-cored castings

Product Expertise

Brake Anchor Brackets and Calipers, Bearing Caps, Crankshafts, Damper Hubs, End Yokes, Engine/Transmission Support Brackets, Idler Arms, Knuckles, Pinion Flanges, and Rear Drum in Hat Adaptors

Phone

231-853-0300

Map and Directions