Auburn Casting Center

Metal Technologies Auburn (MTA) facility is a gray and ductile iron foundry specializing in higher volume castings. Operating controls, particularly in the area of metal treatment, are second to none. Our customers are assured that quality of the material produced exceeds specifications. Metal Technologies Auburn has the latest in vertical molding technology, with two of the 4 lines installed in 2012. In addition, a new core facility was commissioned in 2013 to produce the required cores for some of the facilities high volume products. This was done to increase the quality and competitiveness of our products for our customers.

Facility Information

| Capacity: |

120,000 tons finished Gray Iron and 58,000 tons Ductile Iron |

| Material: |

Gray Iron Classes - G-2500, G-3000, G-35000, and Damped Iron Capability

Ductile Iron Grades - 80-55-06 and 100-70-03 |

| Melt: |

Three 10 ton Inductotherm

100 ton Ajax holding furnace |

| Molding: |

Two Disa 230-X molding lines

Two Disa 231 FAST-X molding lines

Proprietary Koins Expresspour automatic pouring systems (all lines) |

| Finishing Quality: |

Three GF CT-2 Continuous Blast

One Wheelbrator CT-4 Continuous Blast

One Pangborn 34GN Tumble Blast

Three Automated Rotor/Drum Grinders |

| Core Making: |

One EMI SP4040 Fully automated Isocure Core Cell |

| Quality: |

IATF 16949:2016

ISO 9001:2015

ISO 14001:2015 |

Industries Served

Appliance, Automotive, Heavy Trucks, Small Engine, and Trailer Axle

Casting Type and Size

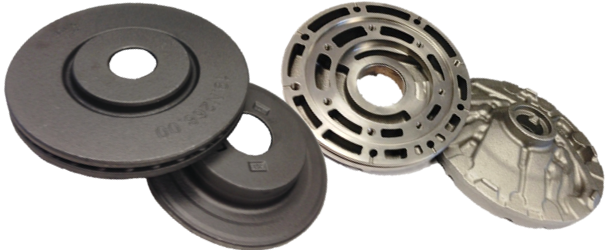

5 to 50 lbs. (2.27 to 22.68 kg) Cored and non-cored medium size castings

Product Expertise

Crankshafts, Intermediate and Clutch Plates, Clutch Brackets, Brake Rotors, Bearing Caps, Drums, NVM Damper Rings, Housings, Transmission Sprockets, Torsion Bar, Adjusters, and Pump Bodies

Phone

260-572-1410